CAN, LIN, and FlexRay: Decoding the Mysteries of Vehicle Communication

Modern automobile systems rely heavily on vehicle communication technologies to facilitate flawless information sharing and cooperative operation amongst the many electronic parts and systems.

It is becoming more and more important to comprehend the underlying communication protocols as the automobile industry moves toward connected and intelligent vehicles.

FlexRay, Controller Area Network (CAN), and Local Interconnect Network (LIN) are three of the most often used vehicle communication technological solutions.

The purpose of this study is to shed light on these technologies by examining their background, characteristics, uses, relative benefits, and drawbacks.

In addition to obtaining insight into upcoming trends and developing technologies that will further impact the automotive landscape, exploring the worlds of FlexRay, CAN, and LIN will help us better understand the complex network of communication systems that underpin the operation of current autos.

Controller Area Network (CAN bus)

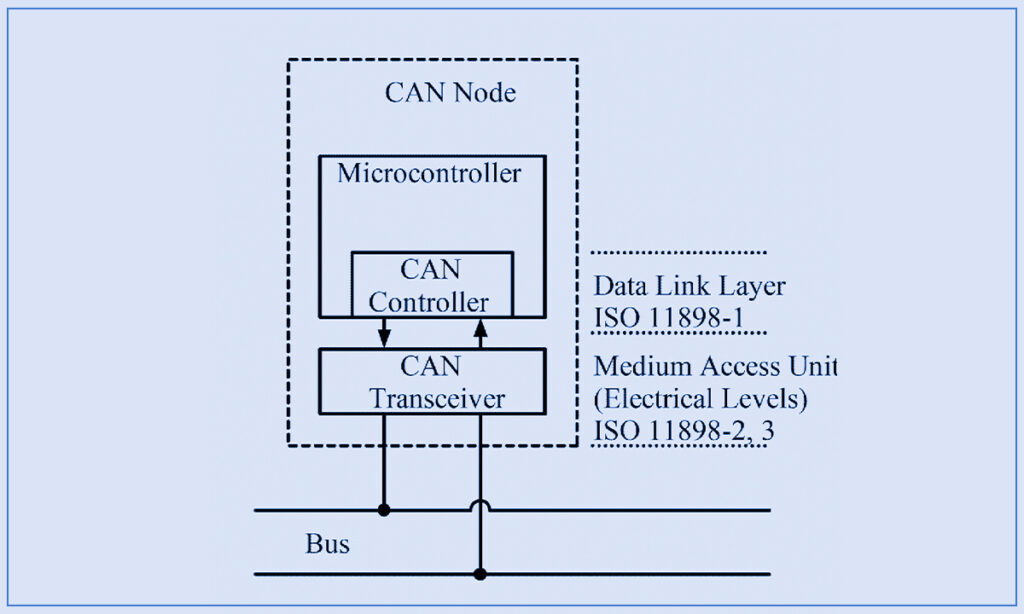

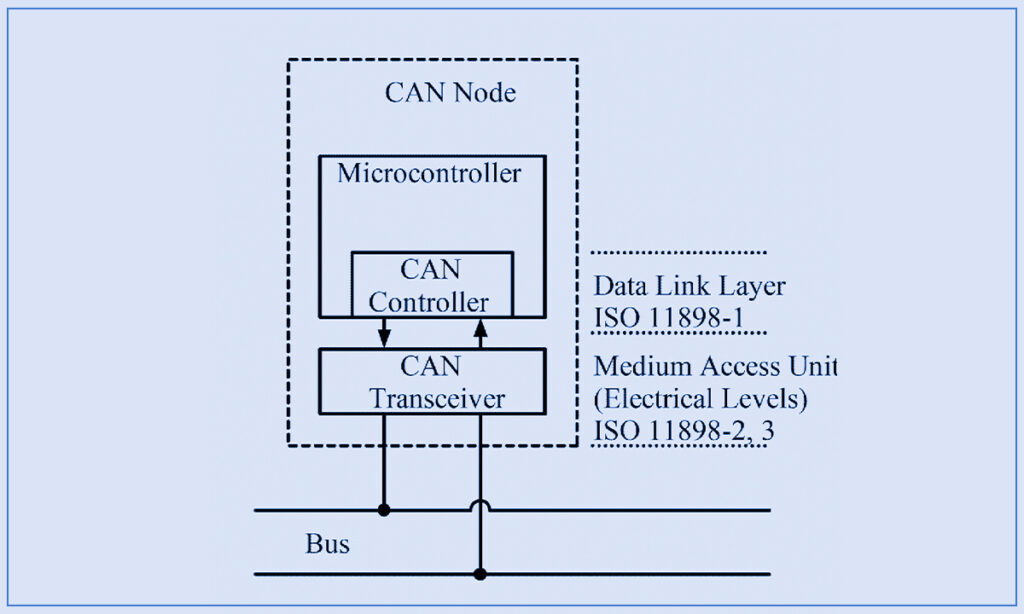

A vehicle bus standard called the Controller Area Network (CAN bus) was created to let microcontrollers and other devices talk to each other’s applications without the need for a host computer.

It’s a message-based protocol that was first created to multiplex electrical wiring in cars in order to save copper usage, but it may also be applied in a variety of other situations.

Each device broadcasts data in a frame serially, but in a way that allows the highest priority device to continue transmission while the others back off if multiple devices are transmitting simultaneously. All devices, including the transmitting device, get frames.

Controller Area Network (CAN) History

In 1985, Bosch created the first version of CAN for use in car networks. Automotive manufacturers used point-to-point wiring systems in the past to link electronic gadgets in their automobiles.

Manufacturers started putting more and more electronics in cars, which led to the creation of large, pricey wire harnesses.

Then, in-vehicle networks took the place of dedicated wiring, lowering the weight, complexity, and expense of the cabling. The industry standard in-vehicle network is now CAN, a high-integrity serial bus technology for networking intelligent equipment.

CAN was swiftly embraced by the automobile sector and, in 1993, it was recognized as a worldwide standard by ISO 11898. A number of higher-level CAN protocols, including CANopen and DeviceNet, have been standardized since 1994.

These extra protocols have been widely embraced by other businesses and have become industry standards for industrial communications.

In the 2000s, The CAN bus expanded its growth more on the Automotive Industry and beyond to various industrial applications.

CAN with the new technology of FD ( Flexible Data-Rate) was introduced around 2011, and it is said to be an extension of the CAN bus protocol which offers higher data rates and maximum payload sizes.

Bosch released CAN FD 1.0 in 2012, which has the specification of using different frames which allows a various data length and also switching to a faster bit rate after the arbitration which is decided.

CAN FD is compatible with existing CAN 2.0 networks so new CAN FD devices can coexist on the same network with existing CAN devices.

As of 2018, Bosch was active in extending CAN standards. New CAN FD devices can live on the same network as current CAN devices because CAN FD is compatible with CAN 2.0 networks already in place. Bosch was actively involved in CAN standard extensions as of 2018.

Controller Area Network (CAN) Applications

- Passenger vehicles, trucks, buses (combustion vehicles and electric vehicles)

- Agricultural equipment

- Electronic equipment for aviation and navigation

- Industrial automation and mechanical control

- Elevators, escalators

- Building automation

- Medical instruments and equipment

- Pedelecs

- Model railways/railroads

- Ships and other maritime applications

- Lighting control systems

- 3D Printers

- Robotics/Automation

Benefits of CAN bus

Low-cost, Lightweight Network

- CAN bus provides a low-cost network that helps to communicate with multiple devices.

- Instead of analog and digital inputs to every device in the system, the Electronics Control Units (ECUs) can have a single CAN interface, and in this way CAN reduces the overall cost and weight in automobile industries.

- When compared to the traditional communication system, this lightweight network requires only less wiring and components so it is easier to install and maintain.

- The specific benefits of a low-cost and lightweight network make it a major choice for many industries like automotive, industrial automation, and medical devices.

Broadcast Communication

- CAN bus allows for broadcast communication, where all sent messages are visible to every device

- As the broadcast communication was allowed by CAN bus, all the sent messages will be visible to every device that is connected to the network

- With this scheme, CAN networks can be modified without requiring the network to add more non-transmitting nodes.

- This Broadcast communication feature allows for more flexibility and scalability in the network, and it is suitable for the various applications that require frequent modification or expansion of the system.

Priority

- CAN bus provides a specific feature which is “Priority”. This sets the priority to every message, for deterministic timing restrictions.

- This Priority comes in when two nodes attempt to send the same messages at the same time. Once the priority is set, the message with high priority goes first and the one with low priority will get delayed.

- Because of this capability, the CAN bus is suitable for real-time applications like industrial and automotive control systems. It ensures that important messages are sent and received on time.

Error Capabilities

- CAN bus has a feature called “Error Capabilities” that includes a Cyclic Redundancy Code (CRC) which is used to check for errors in each frame’s contents

- When a frame contains errors, the network can be notified of the error by sending an error frame, which all nodes ignore.

- The controller can distinguish between local and global errors, and if too many errors are detected, each node can choose to disengage from the network completely or stop transmitting problems.

- The CAN bus uses its error-checking feature to ensure the system’s safety and reliability. It spots and fixes issues on the spot, making it apt for important uses like in medical and car devices.

Local Interconnect Network (LIN)

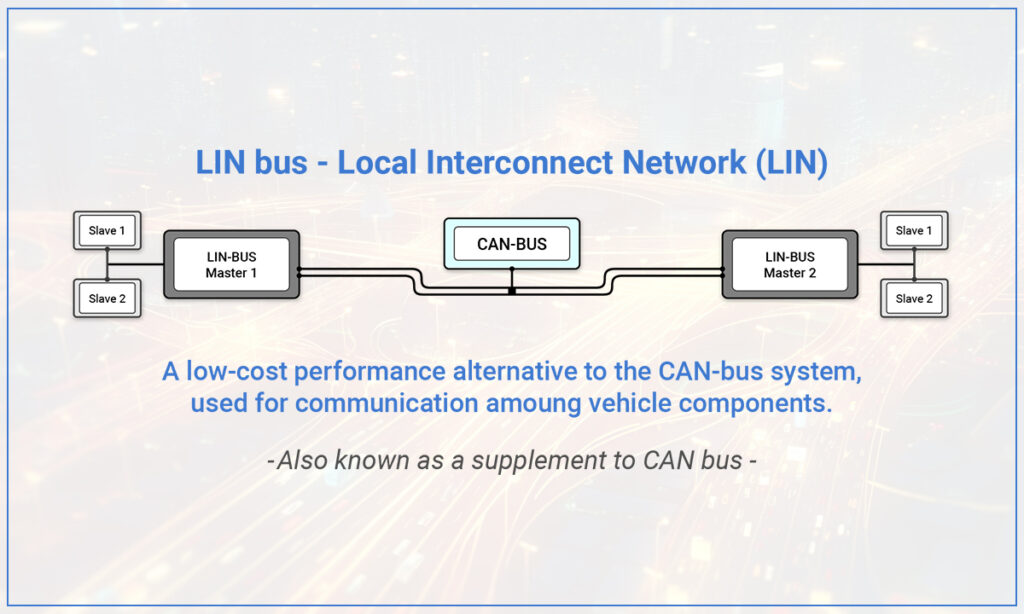

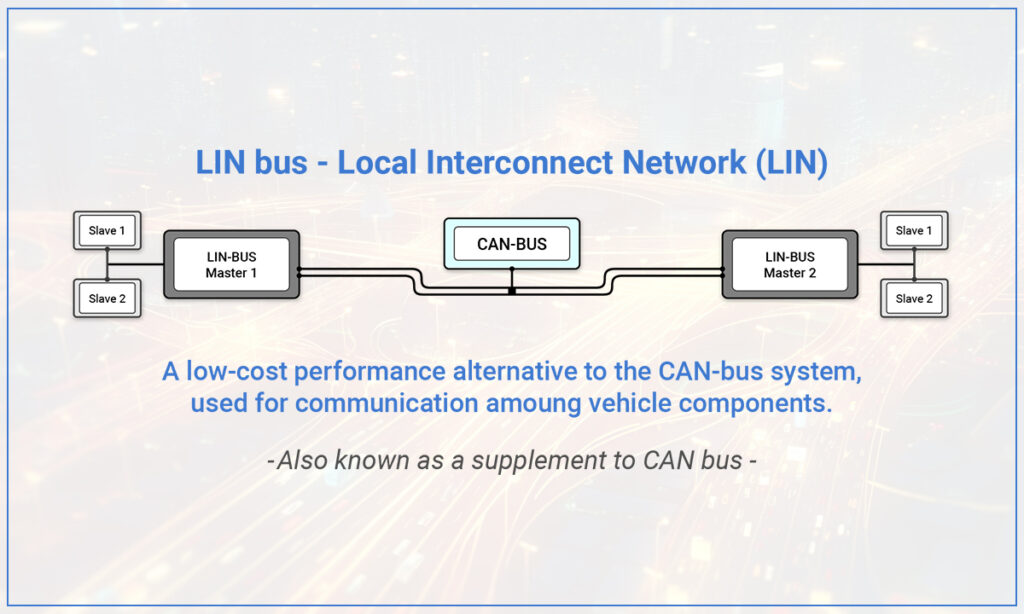

The vehicle’s components communicate with one another via the LIN Bus, which is an acronym for Local Interconnect Network (LIN). It is sometimes referred to as a CAN Bus supplement.

LIN protocol is significantly more affordable than CAN Bus. But compared to CAN Bus, it performs worse and is less dependable.

Because implementing CAN Bus for every component in the vehicle would have been prohibitively expensive, LIN Bus was created. As an alternative, LIN Bus was made available to address this issue and has been a complete success.

Within the network of an automobile, the low-cost serial communications protocol known as the LIN bus efficiently facilitates remote applications.

While it is equally suitable for industrial applications, its primary purpose is to support mechatronic nodes in dispersed automotive applications.

It is meant to be used in conjunction with the current CAN network to create hierarchical networks within automobiles.

LIN History:

The LIN Consortium, which included Motorola, BMW, VW, Audi, Volvo, Mercedes-Benz, Volcano Automotive, and others, released LIN 1.0 in 1999.

Later in 2000, the LIN protocol was updated with the release of LIN 1.1 and 1.2. In 2003, LIN 2.0 was released, bringing significant enhancements that were extensively adopted.

In 2006, the LIN 2.1 standard was released. Following the release of LIN 2.2A later in 2010, which is currently the version that is most extensively used, CAN in Automation standardized LIN in 2016 (ISO 17987:2016).

LIN Bus Applications:

The majority of contemporary cars have twelve or more LIN nodes. They are employed in applications where there is less need for fast data transmission and when a large number of tasks are done digitally.

Common uses consist of:

- Power door locks

- Power windows

- Power seats

- Power mirrors

- Windshield wipers

- Seat heaters

- Heating and air-conditioning controls

- Interior lights

- Climate controls

- Steering-wheel controls (Cruise control, wiper, climate control, radio)

- Sunroof

- Trunk

Benefits of LIN Buses

The Local Interconnect Network (LIN) bus protocol is majorly used in automotive industries, which offers various advantages that make it a preferred choice in the specific domain. Below are some of the key advantages that make the LIN bus the most popular choice for the automotive system.

Cost-Effective Solution:

- LIN Bus has a specific feature of a “Cost-Effective solution” for the applications, which requires only simple and easy interaction between the devices

- Compared to the CAN bus, the LIN bus uses a simpler protocol, that ensures the use of cost-effective hardware and minimizes the overall cost of the system

- This unique feature of the LIN bus makes it a popular selection for applications that require one or more devices to be connected, which includes automotive and industrial control systems

Simplified Wiring:

- LIN Bus with the “Simplified Wiring” helps in reducing the overall cost of the system.

- As the LIN Bus requires only one wire for communication, it minimizes the size and weightage of the system and ensures it is suitable for applications with limited space or weight constraints.

- The Installation time and cost of the system was reduced due to the simplified wiring of the LIN bus

- As the simplified wiring reduces the complexity of the system, the LIN bus can be used for distributed systems that require one or more devices that need to be connected.

Low Power Consumption:

- Another feature of the LIN bus is “lower power consumption”, which makes it perfect for applications that need energy-efficient solutions

- It also minimizes the power needs and the requirement for additional power management components.

- Some applications will have only limited power sources, such as battery-powered devices and there comes LIN’s lower power consumption feature

- It also reduces the heat generated by the system, which helps in improving the reliability and gives a long life for the devices.

Real-Time Communication:

- Here is another feature of the LIN bus which is “real-time communication”. It provides real-time communication between the devices and makes it suitable for applications that require fast and reliable communication

- It allows the system to reply earlier that can change in the environment and it also improves the overall performance and efficiency of the system

- It easily detects and responds to the bugs quickly for the improvement of the reliability and the safety of the system

- This benefit of real-time communication is one of the popular choices for applications as it allows for fast reliability on various systems like automotive, industrial control, and medical devices

FlexRay

The FlexRay Consortium created the FlexRay automotive network communications protocol to control on-board vehicle computing.

Though more costly than CAN and TTP, it is intended to be quicker and more dependable. 2009 saw the dissolution of the FlexRay consortium, however, ISO 17458-1 through 17458-5, the FlexRay standards, are still in use today.

FlexRay is a time-cycle-based communication bus that is divided into static and dynamic segments for event-triggered and time-triggered communications. Its goal is to provide high data speeds and fault tolerance.

History of FlexRay:

The goal of the FlexRay protocol was to provide a standardized networking communication protocol that was quicker and more deterministic. The team from the FlexRay collaboration built the first prototype back in 1999.

The initial protocol was restricted to the SAE group and released later in 2004 for application use. However, as of right present, ISO17458-5 through ISO174518-1 include it in their standards. The BMW X5 E70 cars were the first to adopt this protocol in 2006.

However, a new BMW-7 series known as the F01 marked the beginning of the actual deployment and execution of the FlexRay protocol in 2008.

Applications of FlexRay:

- Electronic power steering. (Steering-by-wire).

- Advanced driver assistance systems.

- Power train.

- Body control module.

- Battery management system.

- Antilock braking system.

- Vehicle stability control (VSC).

- Vehicle stability assist (VSA).

Benefits of FlexRay

FlexRay offers several benefits over other communication protocols. Some of these benefits include:

High-speed communication:

- To transmit a large amount of data quickly and efficiently, the features of FlexRay are used. It also improves the overall performance of the system.

- It also provides the low-latency, which ensures the system should respond quickly to the changes that occur in the environment, and it also improves the overall safety and reliability of the system.

- The benefit of high-speed communication minimizes the time required for transmitting the data and it also allows the system to handle large amounts of data streams simultaneously.

- The high-speed communication suits the complex system that requires quick and reliable communication, and that makes it a more popular choice for automotive applications.

Redundancy and fault tolerance:

- FlexRay has an incredibly dependable dual-channel communication technology that offers fault tolerance and redundancy features.

- If one channel fails in the FlexRay, the redundancy makes sure that the system remains operational and also improves the overall reliability of the system

- The system detects and debugs the errors quickly because of the fault tolerance feature of FlexRay and it also reduces the risk of the system the failures.

- The fault tolerance and redundancy of FlexRay are perfect for important applications that require high levels of safety and dependability, like industrial control systems and automobiles.

Predictability:

- The Time-Triggered protocol of the FlexRay makes sure that the data transmission is extremely predictable making it perfect for important applications

- It allows the system to provide a quick response to the changes that occur in the environment and also it helps improve the overall safety and reliability of the system

Scalability:

- The unique feature of the FlexRay is Scalability, which allows it to be used both in the small and large automobile systems

- It gives a flexible solution for applications that need a communication system that can be used for the improvement of the system’s needs.

Conclusion:

To summarize, the automotive sector uses three main protocols for communication: FlexRay, Local Interconnect Network (LIN), and Controller Area Network (CAN).

As the foundation for the majority of in-car communications, CAN offers different electronic control units a dependable and affordable option.

For non-critical systems, LIN is a more affordable and straightforward option. On the other hand, FlexRay is a high-performance protocol that is frequently seen in autonomous cars and sophisticated driver assistance systems.

It is made for applications that require exact timing and fault tolerance. In order to optimize car communication systems as automotive technology develops, engineers and designers must have a thorough understanding of the benefits and uses of various protocols.